| Specialty Cable Reels |

Static-Discharge Reel

|

Welding Reel

|

Ground-Fault Reel

|

Hazardous-Location Reel

|

Mill-Duty Service Reel

|

| Overview |

Woodhead® Aero-Motive® Specialty Cable Reels are spring-powered for both vertical and horizontal payouts for the most

demanding environments and industrial applications to ensure safety.

Ground-Fault Cable Reels are sturdy, compact, spring-driven cable reels that provide convenient and efficient methods of

retracting and storing equipment-ground cables on electric-utility service trucks, requiring minimum maintenance.

Electric-Welding Reels are built to high-quality standards with a containerized mainspring, safety declutching drive hub

and weather-tight design. Standard models cover the most common wire sizes: 4, 2, 1, 1/0 and 2/0 AWG. Additionally, Woodhead offers

three platforms to meet customer needs for different cable lengths.

Hazardous-Location Reels are offered on all 1100- through 2800-series reels and are Factory Mutual Listed. Reels are available

with 3 to 10 conductors (35A slip rings) in 16 to 10 AWG, or 3 or 4 conductors (75A slip rings) in 8 to 4 AWG, and comply with

requirements defined by the National Electric Code:

• Class I, Div I, Group C & D

• Dust-Ignition proof for Class II, Div I, group E, F & G

• Suitable for Class III, Div I, Outdoor Hazardous locations

Mill-Duty Service Reels are offered on reels with external spring-driven motors and are designed to make installation and

service faster and easier than any other brand available. Mill-duty service reels are recommended for critical processes where

downtime must be held to an absolute minimum, such as steel mills. Mill-duty service reels include series 2000 through 2800. Two

junction boxes provide quick access for all working and lead-in cable connections, fast-tensioning end plate to add or remove

tension without disassembling the entire reel and quick-change spring motor.

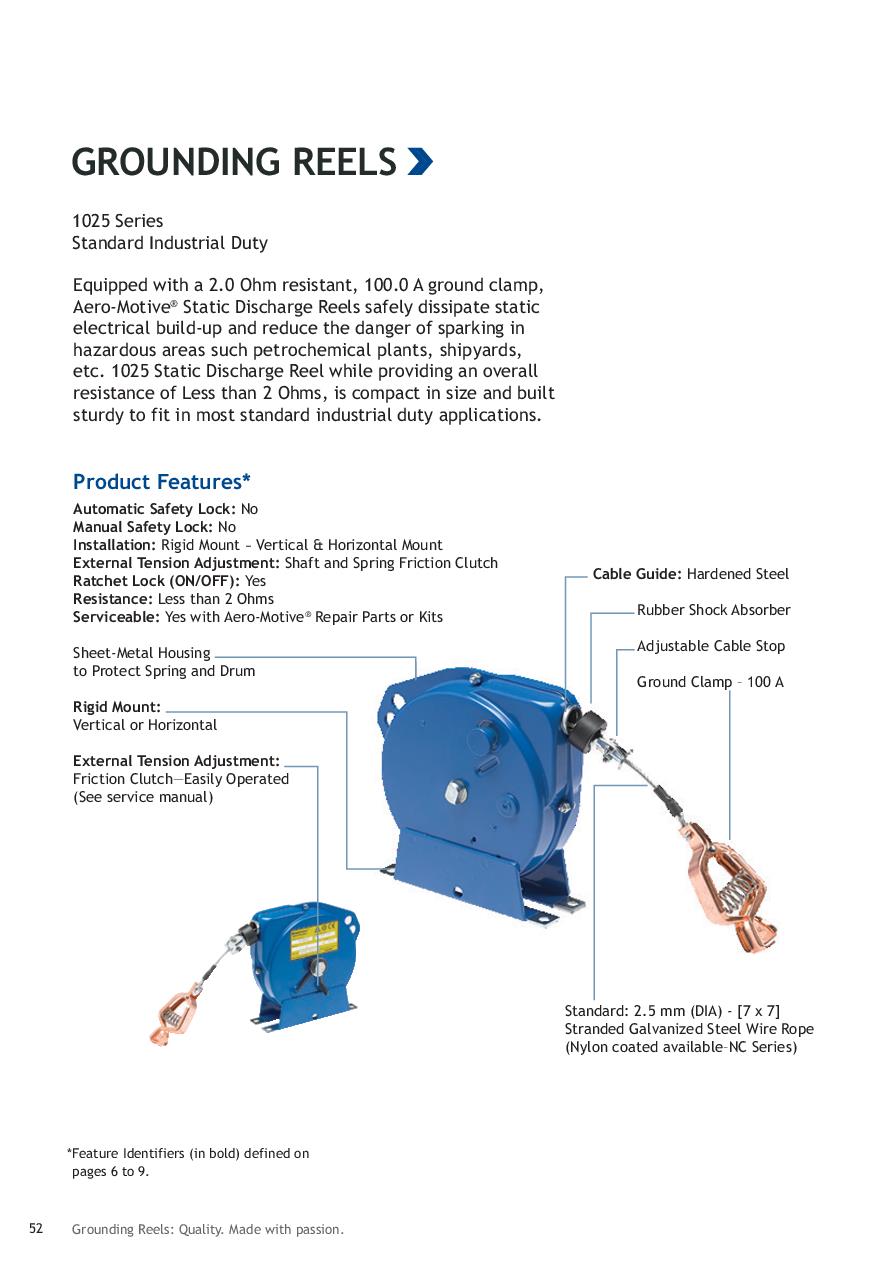

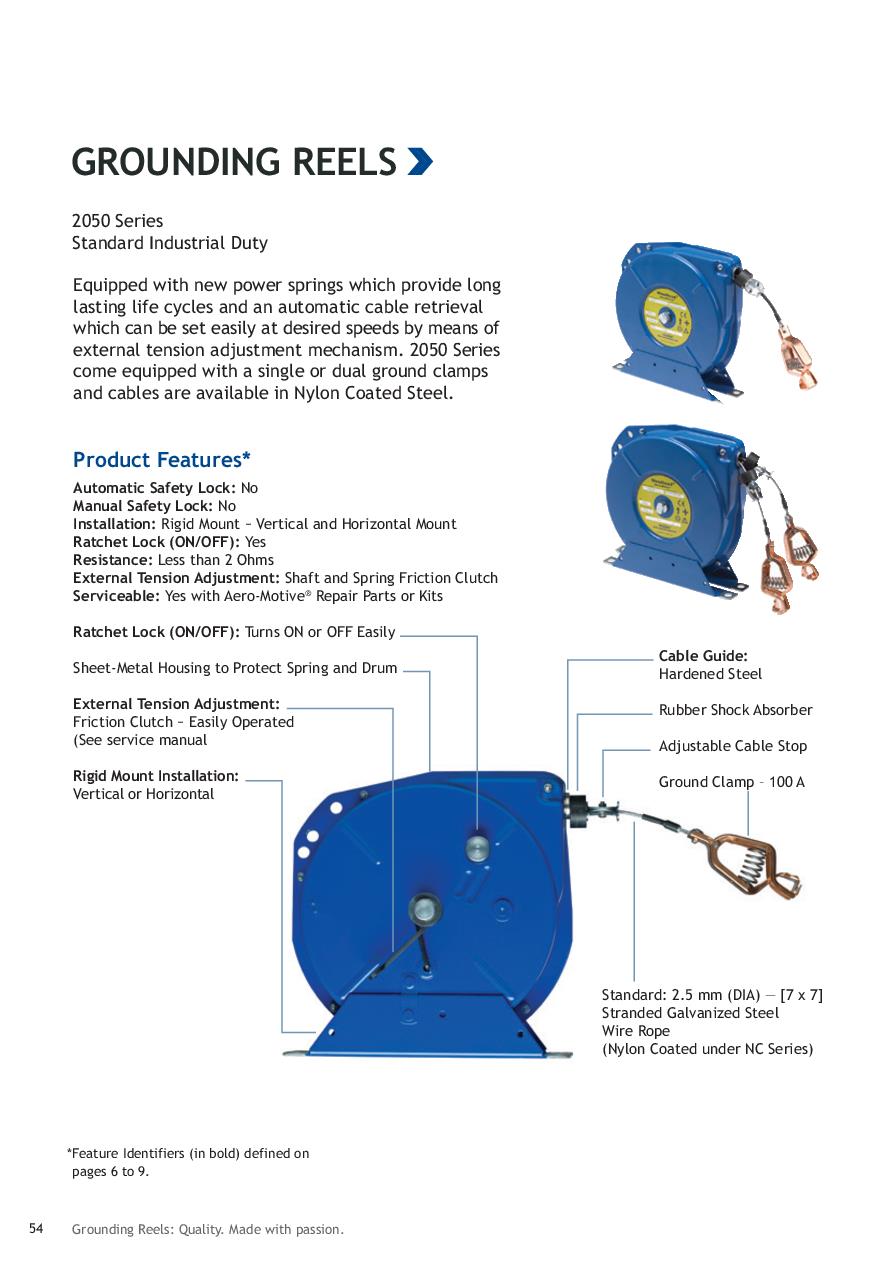

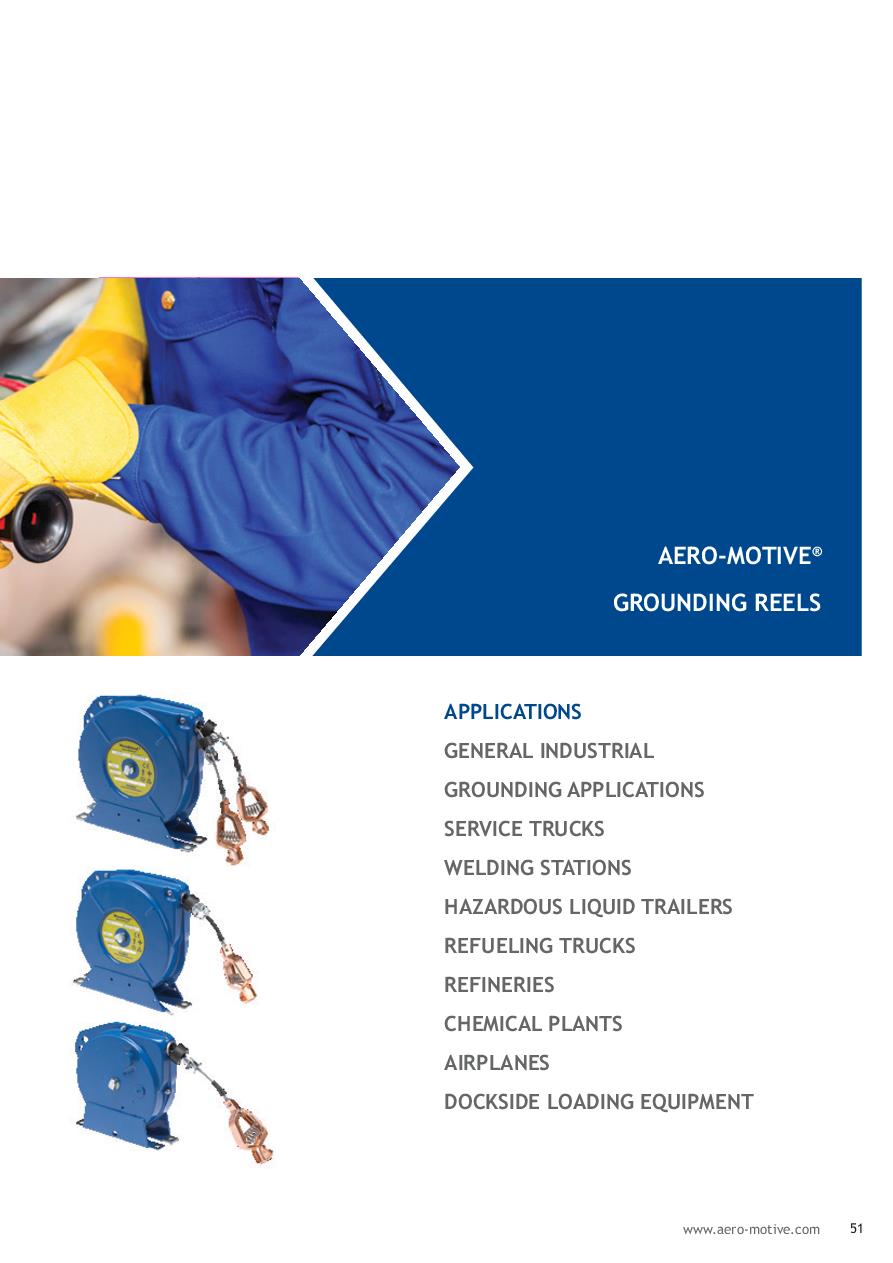

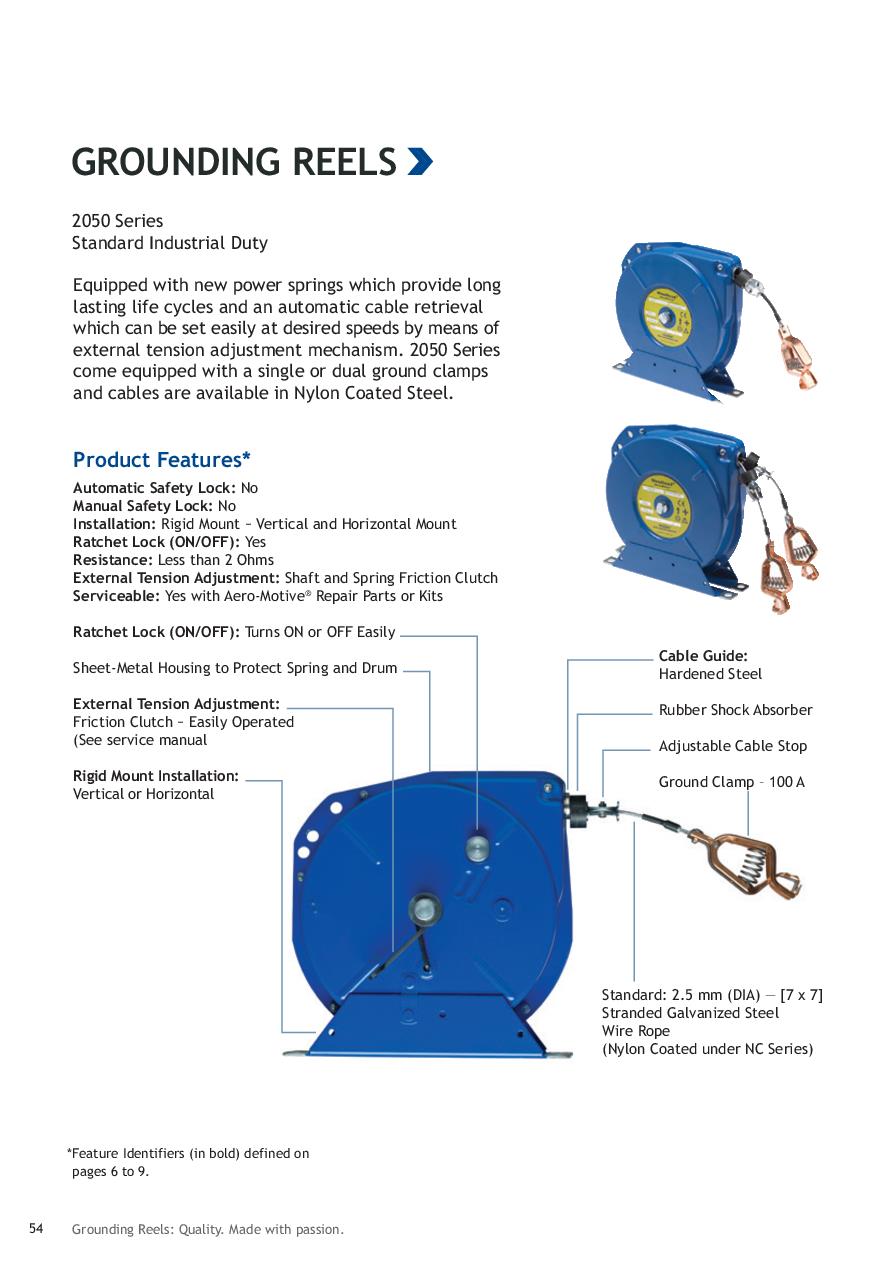

Static-Discharge Reels are steel-constructed, instant-action, lock-and-release reels with a galvanized-steel aviation cable

designed to eliminate static build-up from service vehicles and other equipment. Static-discharge reels are equipped with 100A

grounding clamp, rubber bumper and cable resistance of 1 Ohm throughout the entire unit.

Documentation

• Cable Reels Catalog

• Cable Reel Series 1051, 5XXXXL Service Manual

• 2050 Series Static Discharge Reel Service Manual

• Welding Reel ERA 4000 Service Manual

• Ground Fault Cable Retractor GR900 Series Service Manual

• Ground Fault Cable Retractor GR1000L Service Manual

|

|

|

| Features & Benefits |

Applications |

Robust frame construction

• Allows mounting onto service vehicle (certain models only)

External spring on mill-duty reels

• Provides fast spring replacement for critical processes

External spring adjustment on mill-duty reels

• Allows tension and de-tension of spring without removing service cable

Design reel up to 36 conductors

• Meets various application requirements

|

|

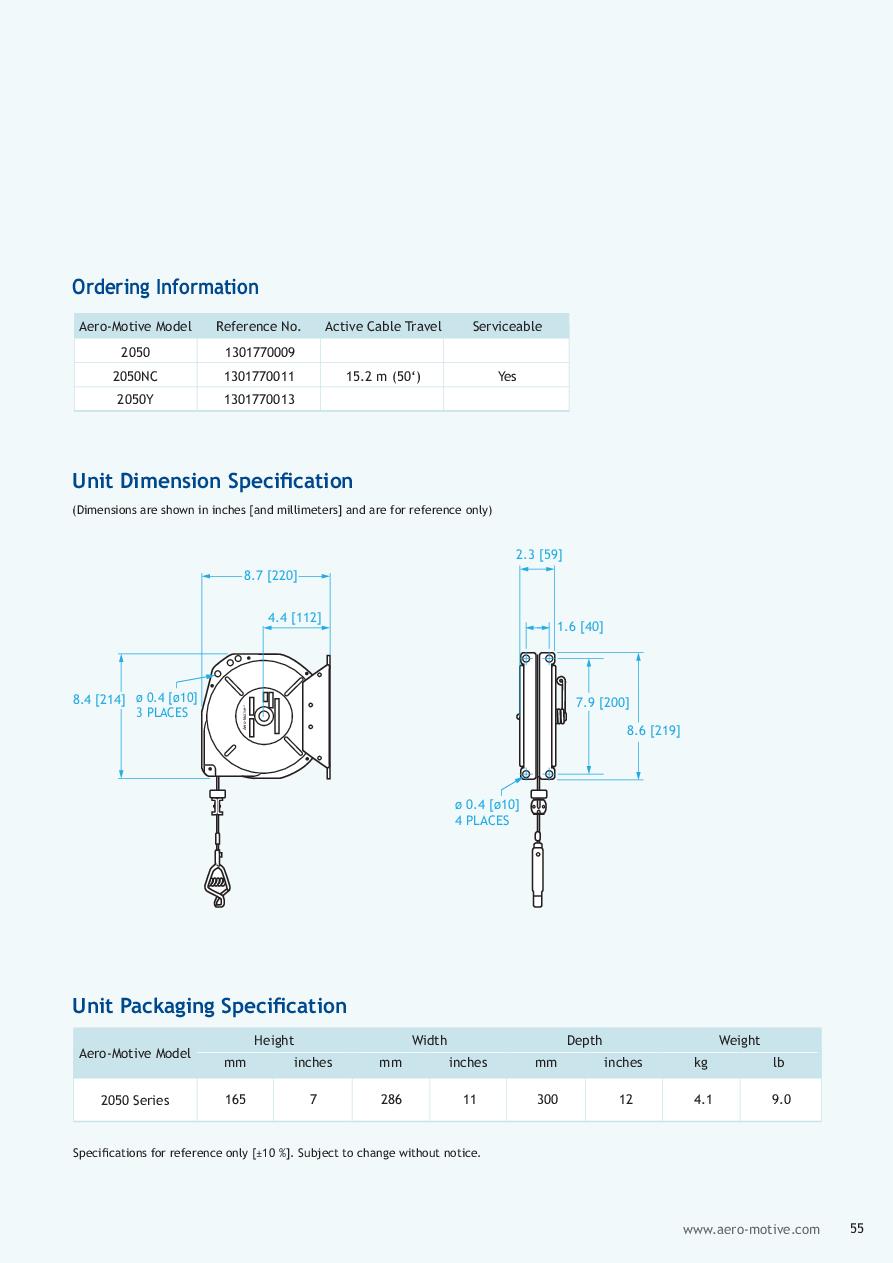

• Aircraft maintenance hanger

• Chemical plants

• Military bases

• Moving equipment

• Shipyards

• Steel mills

• Utility service vehicles

• Wastewater treatment

|

|

|

|

|

|

|